Education:

- B.Sc. (Animal Sciences and Agricultural Technology) Silpakorn University, Thailand

- M.Sc. (Biotechnology) Kasetsart University, Thailand

- Ph.D. (Nanomaterials Science) Kasetsart University, Thailand

Research Interests:

1) Natural rubber

2) Rubber foam

3) Self-healing materials

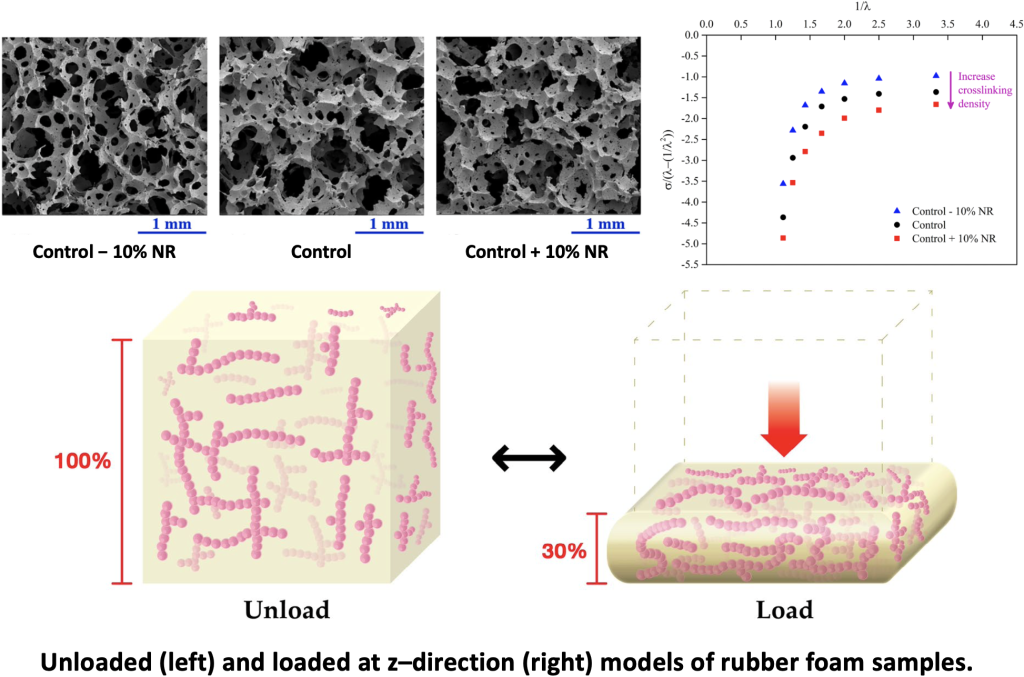

Natural rubber (NR) or para rubber is an important economic crop of Thailand. Thailand is the world’s largest producer and exporter of NR. Generally, NR foam can be prepared by the Dunlop method using concentrated natural latex, which is prepared by fresh natural latex with chemical agents. NR foam is an interesting natural polymer foam which can be made into lightweight products and is suitable for comfort applications such as pillows and mattresses, cushion foam, etc. Normally, NR foams are porous, elastic and have a ventilated surface. NR foam has good elasticity, and its mechanical properties can be tuned with the choice of the preparation process, chemical agents, filler loading, etc. So, NR foam is still interesting subject to explore in the world market, especially the new preparation method, nano-chemical agents to improve the foam properties but not increase its weight, etc.

Self-healing property is also an interesting subject to repair the damage in materials. This relatively new part of material deals with self-assembly or molecular assembly that results from the association of two or more chemical species held together by intermolecular interactions. The self-healing mechanisms may relate to viscoelastic properties allowing the molecular mobility to heal the damage and the surface energy creating the contact between two damaged areas. The self-healing of polymers can be succeeded by both covalent and non-covalent networks. Moreover, self-healing materials can be utilized in advanced applications such as biomimetic, bio-inspired, and smart materials in the robotic field. Therefore, this self-healing property is still not well-understood, we also need more technical knowledges to elucidate and develop the self-healing polymer.

Selected publications

1. Buaksuntear, K.; Limarum, P.; Suethao, S.; Smitthipong, W. Non-covalent interaction the self-healing of mechanical properties in supramolecular polymers. Int. J. Mol. Sci., 2022, 23, 6902.

2. Suethao, S.; Phongphanphanee, S.; Wong-ekkabut, J.; Smitthipong, W. The relationship between the morphology and elasticity of natural rubber foam based on the concentration of the chemical blowing agent. Polymers, 2021, 13, 1091.

3. Chollakup, R.; Suethao, S.; Suwanruji, P.; Boonyarit, J.; Smitthipong, W. Mechanical properties and dissipation energy of carbon black/rubber composites. Compos. Adv. Mater., 2021, 30, 5476.

4. Suethao, S.; Ponloa, W.; Phongphanphanee, S.; Wong-ekkabut, J.; Smitthipong, W. Current challenges in thermodynamic aspects of rubber foam. Sci. Rep., 2021, 11, 6097.

5. Suethao, S.; Shah, D.U.; Smitthipong, W. Recent progress in processing functionally graded polymer foams. Materials, 2020, 13, 4060.